Full Html

Vol 2 Issue 8 (Special Issue)

Triboelectric Nanogenerator Based on PTFE Plastic Waste Bottle and Aluminum Foil

Pages: 203-213

Doi: 10.54738/MI.2022.2803

Doi URL: http://doi.org/10.54738/MI.2022.2803

Fahad Ali 1 , Zaryab Hussain 1 , Muhammad Numan 2 , Batool Fatima 3 , Muhammad Najam ul Haq , Saadat Majeed ?? 1 , Touseef Ahmad 1

1 Division of Analytical Chemistry, Institute of Chemical Sciences, Bahauddin Zakariya University, Multan, 60800, Pakistan

2 Graphene & Advanced 2D Materials Research Group (GAMRG), School of Engineering and Technology, Sunway University, Kuala Lumpur, Malaysia

3 Department of Biochemistry, Bahauddin Zakariya University, Multan, 60800, Pakistan

In this work, authors used waste plastic bottle and aluminIum foil further modified with graphene oxide as triboelectric material to construct a triboelectric nanogenerator (TENG). The proposed device is based on a single electrode system. The operating mechanism involves the generation of energy by tapping the surfaces with hand or finger. TENG material provided good response and charge retaining capacity. The device is eco-friendly; provide easiness, and simplicity of process. The substrate material is of inertness nature so can be used in wet conditions as well. The results were conducted by measuring the open-circuit voltage, short circuit current, total charge density, and power density at different frequencies from 1Hz to 3Hz. The TENG generated approximate open-circuit voltage, short-circuit current, charge density, and maximum power density values of 1400 V, 45 µA, 120 nC/m2, and 300 μW/cm2, respectively by finger pressing and releasing. The application was run to charge 2 nF and 10 nF capacitor by TENG and successful results were obtained. This study provides an effective method for developing a cost-effective TENG without the use of complex surface micro-/nano-texturing.

Keywords

Triboelectric nanogenerator, Mechanical energy, Tapping, Aluminum foil, Waste plastic bottle, Single electrode

Now days, flexible and wearable electronic gadgets have attained attention of scientific personnel and technologists on the account of plentiful properties compared to previously existed electronic circuits and gadgets of versatility, delicacy and comfort 1, 2, 3, 4. Integrating these properties with different functionalized materials and particular structures has led the way to the execution of adaptable gadgets in various sensing and monitoring fields 5, 6, 7, robotics 8, 9, 10, renewable energy generation, 11, 12, 13, 14 and motion sensing 15, 16, 17. The currently advancing significance of self-powered gadgets has initiated the designing and fabrication of integrated electronic systems with energy generating tools. Although, smart, compatible and versatile electronic systems for substituting? batteries and energy supplying devices has opened the path for scientists and technologists to design flexible, miniaturized and smart energy sources. In recent year a large number of the low power electronic devices have been introduced like implantable, medical and non-medical sensors, GPS and communication devices, to enhance the quality of life. These electronic devices required electric power from few microwatts to miliwatts. The conventional power sources and batteries are described by large size, confined capacity, need of periodic replacement and recycling. The material used in these batteries is hazardous to human life and environment. Moreover, the conventional power sources and batteries cause great hindrance and barrier in miniaturization of devices due to oversize and volume. Many new energy generating and power sources have been investigated and recommended in recent years. Mechanical energy producing from surrounding motions or frictions is potential and efficient field. Variety of ways to convert mechanical energy into electrical energy have been executed in last few years i.e. electromagnetic 18, 19, 20, piezoelectric, 21, 22, 23, 24, 25and triboelectric generation 26, 27, 28, 29, 30. Triboelectric is one of the promising way to harvest energy effectively 31. In triboelectric generation, electrification of material’s surfaces caused by contact between two materials. During contact, friction causes charge separation and it totally depends on the polarity of materials in contact 32, 33. In 2012, Z. L. Wang was first who applied triboelectric nanogenerator to convert mechanical energy into electrical energy at nano level. From then, TENG has out spread and developed with advent of improved TENG designs and with various ecofriendly functionalized materials. TENG devices offer plenty of characteristics as compared to other energy generating sources and sensing devices i.e. smart, small, thin, flexibility, and versatility. These are free from large coils and magnets as in existed electromagnetic generators and work at low frequency ranges i.e. ? 10 Hz. They are fit for the application concerning body movements, ambient frictions and ocean waves. 34, 35, 36, 37 Many types of TENG based power devices have been reported globally, devised with various modes of operation. TENG power devices works on four fundamental operating modes i.e., contact-separation mode, sliding over mode, single electrode TENG, and suspended TENG layer mode. 38, 39, 40, 41. These operational modes require two different materials having proper insulation between each layer as well as with proper electrode connections. The changes and displacement in any of the triboelectric layers causes the changes in the electrostatic charge movements. The electrostatic movement of charges generates the potential difference between the two electrodes by breaking the electrostatic status of the TENG assembly. The periodic back and forth movement of the both layers over each other produces the potential in both directions between the electrodes. The negative and positive peaks in the TENG output produce the AC signal. In this regard, the finding and manipulation of new materials is under way 42, 43. Moreover, the development of new methodologies to increase the rate of triboelectric charge transfer via surface modification with nanostructure configuration, porosity and fabrication 44, 45. Currently, various material have been employed as triboelectric surfaces including poly-dimethylsiloxane 46, kapton 47, poly-ethyleneterphathalate 47, self-synthesized poly-tetrafluoroethylene (PTFE) 48, and parylene C 49. These materials are expensive, less available, and difficult to synthesize, and produce hazardous waste during synthesis.

This paper describes the fabrication of triboelectric nanogenerator from low cost and easily available material. The TENG device consists of novel combination of PTFE waste bottles cut into appropriate pieces as a substrate, modified with aluminum foil and graphene oxide material. The proposed device is based on single electrode system. This fabricated TENG works on contact-separation mode. The operating mechanism involve the generation of energy on tapping two surfaces with hand or finger. The TENG material provided good response and charge retaining capacity. The device is ecofriendly provide easiness and simplicity of process. The Chronoamperometry was performed to manipulate the current generation ability of fabricated TENG assembly.

Graphene oxide (GO) was synthesized via modified Hummer’s method 50. Briefly, sulfuric acid and phosphoric acid in 9:1 ratio were taken together and mixed thoroughly. 0.33g of graphite powder was added in acidic solution and stirred for 60 mins. 1.32g of KMnO4 was added into the above solution slowly in a span of 40 mins with stirring. The solution kept on stirring for additional 6 hrs until the color of solution appears dark green. In order to decrease the excess amount of KMnO4, 0.75 mL of H2O2 was introduced drop wise to neutralize the effect of excessive KMnO4. The solution was kept on stirring for additional 10 mins. Addition of H2O2causes highly exothermic reaction; the mixture was cool down up to room temperature. After cooling, the as synthesized GO was washed with HCL and deionized water (1:3) and centrifuged at 6000 rpm. Washing was repeated several times to get the neutral graphene oxide. After the washing, synthesized GO was dried in drying oven at 60 °C to obtained powder graphene oxide.

The design and fabrication process of the GO SP-TENG device is schematically shown in Figure 1. The main material used in the fabrication of the TENG was plastic PTFE waste bottles which is readily available for the cold drinks and water bottles, obtained from household wastes. The plastic bottle was selected randomly without concerning manufacturer. The bottles were washed with water again, dried in oven at 60 oC, and were cut from the middle in desired shape using house hold scissor. The length and width of the sheets was 3 × 6 cm2. (Figure 1a ) PTFE sheets were washed again with the help of acetone and ethanol several times to remove dust particles from the surface before further use. The ordinary aluminum foil used for cooking and storing purposes in houses is collected and used as an electrode material. The aluminum foil was cut into 3 × 6 cm2 in length and width. The aluminum foil surface was cleaned by successively washing with acetone and ethanol to removes the impurities. The foil was adjusted on the inner side of the plastic sheets with double sided adhesive tape to impart the stability against tearing. The double sided tape act as a positive TENG layer. The holes were created on the upper side and lower sides of the TENG device for electrical connections. The electrical connections were established with wires obtained from discarded water bath wire available in laboratory. This whole assembly was the one complete triboelectric nanogenerator cell. Towards the lower side of uniform layer of graphene oxide of thickness 500 μ m. The electrical connections were designed over graphene oxide coated layer. The graphene modified plastic layer performs as a negative TENG layer. (Figure 1c) The overall cell was put into the oven for drying purposes at 40 oC for 30 minutes. The current produced through this TENG is alternating current (AC) voltage. The AC voltage was converted into DC voltage by adding rectifier circuit in triboelectric setup. The working principle of rectifier is very simple and consists of diodes and capacitor. The diodes are very useful for converting AC to DC because it transfers electric current only in forward biased, when they operate as reverse biased, they are unable to pass electric current. The capacitors are very useful while construction of the rectifier because it filters the converted DC voltage by diodes and make them more linear than previously, produced by the diodes.

Figure 1: Typical illustration of triboelectric nanogenerator and with rectifier

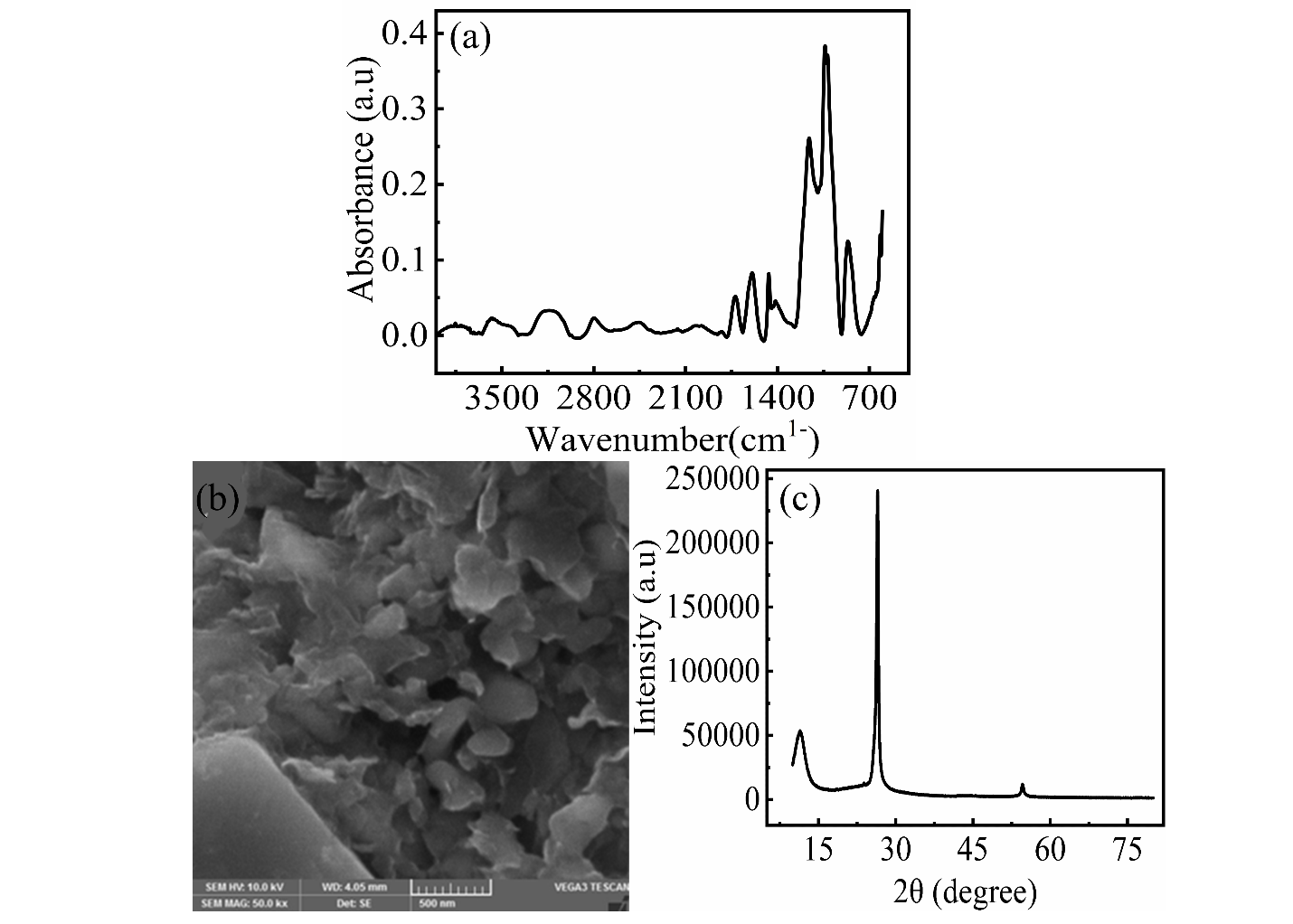

The synthesized graphene oxide was characterized by Fourier Transform Infrared spectrometry (FTIR Bruker, USA), scanning electron microscopy (SEM JSM-IT700HR-JEOL, Japan) and X-ray diffraction (PXRD Bruker, USA). (Figure 2) FT-IR spectrograph (Figure 2a) showed peaks at 3400 cm-1, 2903 cm-1, 2171 cm-1, 1713 cm-1, 1655 cm-1, 1250 cm-1 and 1103 cm-1. The peak at 3400 cm-1 appeared for -OH functional group and peak at 2903 cm-1 for single bond C-H. The peaks at 1713 cm-1 confirms presence of C=O functional groups on graphene oxide. While the peaks at 1655 cm-1, 1350 cm-1 and 1103 cm-1 showed the presence of C=C and C-O functionalities. All the peaks presented in FTIR spectrum described above and approved the synthesized material as graphene oxide. Scanning electron micrograph taken by SEM shown in Figure 2b. The micrograph was taken by SEM providing the high voltage of 10 kV, magnification 50kx and scale of 500 nm. As synthesized graphene oxide, seem to be flake like structure as shown in micrograph. It also shows graphene oxide flakes with sheath backbone. Flake like structures on sheath backbone will offer high surface area. High surface area provide large surface for functional groups to be generated. Powder XRD caused by Cu Kα having 0.154 nm wavelength was performed and spectra is shown in Figure 2c. The peak appeared at 2θ= 31.4º for graphite powder and at 2θ= 13.1º for graphene oxide. The peaks were sharp and clear. This shift in 2theta value from 31.4º to 13.1º as graphite transfer into graphene oxide was due to generation of (002) facet diffraction of GO. This change in peak position may also cause by change in d-spacing from 0.35 to 0.59 nm. The peaks value and shift in peak values confirmed the oxidation of graphite powder into graphene oxide.

Figure 2: Characterization of graphene oxide A) FTIR spectrum B) SEM micrograph C) XRD pattern

Figure 3: A. Working mechanism of triboelectric nanogenerator; B. Charges generated on surfaces of aluminium foil electrode and graphene oxide surface following contact and separation mode.

The working principle and mechanism of the of low cost and flexible TENG is schematically illustrated in Figure 3. The TENG work on the principle of tribology. It is the phenomena in which different materials get charged on contacting by other surfaces. Some materials get positive charge and some materials get negative charge according to their place in triboelectric series. Moreover the triboelectrification process may occur between different dielectric layers or between dielectric or metal layer. This mode for energy generation is also called as “contact separation mode”. In the present study TENG aluminum foil and graphene as low cost materials were used for harvesting nano-energy. (Figure 3a) According to triboelectric series, graphene get negative charge after contacting with aluminum while aluminum gets corresponding positive charge. (Figure 3b) When both surfaces come in contact, electron transfer from the GO to the aluminum layer. (Figure 3c) The electrical difference is produced with the separation of two layers on release. This kind of the differences drives the electron to flow through external circuit from one surface to other surface and causes positive triboelectric charges available on the surface and produces output current signals. (Figure 3d) The contact and separation mode for nanoenergy harvesting is very simple, low cost and easy to design.

In present work, initially when two-layers are separated there was no charge on the both surfaces. As the force is applied over the surfaces of the TENG the two surfaces come in close proximity of each other and get corresponding charges. However at initial stage there was no flow of current across the resister. When applied force removed, layers get separated from each other and cause generation of potential difference across the layers, which in turn produces the flow of electrons. The electrons as a current passes from lower layer of graphene oxide (negative half cycle) through the external circuit and reach the upper layer of aluminum foil electrode (positive half cycle), complete the electrical circuit, and get equilibrium position. As a result electric signals are produce and detected by triboelectric nanogenerator. As the force on the triboelectric nanogenerator again applied, electron will flow in the opposite direction as described above and causes negative half cycle and collectively produced AC voltage. The AC signal is produced thus converted to DC signal with the help of integrated rectifier. Electric performance results of SP-TENG was calculated by following literature 51. Open circuit voltage is given as in equation 1.

Voc=σx(t) ε0 1

Where x(t) is the distance between two electrodes as a function of time. σ is the charge density accumulated on the triboelectric material and εo is the permittivity of the free space. The short circuit current calculated by using following equation 2.

Isc= σ A d0 v(t)[d0+xt]2 2

Where Isc is the short circuit current, which is directly proportional to total charge density accumulated on the triboelectric layer. d0 is the effective dielectric thickness, A is the surface area of the electrodes ,and v(t) is the mechanical motion of the generator ,which is inversely proportion to square of the distance between the triboelectric material coated electrode 51.

Figure 4: Approximate values of Voc and Isc at 1 Hz (a,d), 2 Hz (b,e) and 3 Hz (c,f) frequencies. Optimized Conditions: TENG size: 3 × 6 cm2, maximum separation distance: 4 mm)

Figure 5: Short circuit current SP-TENG at slow (a), medium (b), and fast (c) hand tapping: B. Electrical performance of TENG based on PTFE and graphene oxide a) voltage b) current; the relationship between power density and resistance of SP-TENG; charge density per unit area accumulate on the surface of tribo-electrodes.

Figure 4 is the evidence of present idea and nanogenerator device. The output performance of the TENG is based on contact separation mode. Therefore it is largely depend upon the frequency, separation distance, and device size. Figure 4, exhibits the dependence of the VOC and ISC values of TENG on contact frequency at optimized value of device size and separation distance. The experiments were performed for short circuit current and voltage at different tapping frequencies from 1 Hz to 3 Hz, and dramatic change in the Voc and Isc values was observed. The results measured at three different tapping frequencies depicts that electric output increases as the tapping frequency of the nanogenerator increased. In the start less current was generated because less amount of charge is accumulated at two electrodes i.e., charge density was low on electrode surfaces. However, with the passage of time, charge density was increased on increasing tapping and as a result current value increased. TENG showed the maximum current of 45 μ A at 3Hz. The graphene oxide based TENG was connected to potentiostat via alligators. The rectifier converted the AC current generated by TENG into DC current. The results showed only positive current signals. Although, graphene oxide coated on aluminum foil played significant role in enhancement of electron generation and charge transfer to external circuit. The single unit TENG generated maximum current up to 45 μ A at 3 Hz which was low value to use TENG in real time energy applications. Therefore, in order to enhance the current value, the two TENG units were arranged in series and connected to potentiostat.

The results explain the electrical performance as open-circuit voltage (Figure 4 a, b, c) of triboelectric nanogenerator on different vibrating frequency. The frequency is related to the external force provided per unit time, to the device, which ultimately generate contact–separation phenomena by which electrons flow from one triboelectric layer to the other. When the applied force was 5N, the obtained frequency was 1 Hz. The trend increased the vibrating speed, hence flow of electron from one layer to another layers remarkably increased. Moreover, high output results at lower frequency revealed the excellent energy harvesting ability of the device, which is very noticeable feature in triboelectric field. The maximum open circuit voltage after rectification, achieved by present device was approximately 1400 V.

At lower frequency electric output signal after rectification was observed in the range between 0-150. Voc and Isc were observed in the range between 0 -1.5 μ A. Electrical performance of triboelectric nanogenerator completely depend upon the surface properties and potential of the material to lose or gain electrons 52. Moreover, electrical signal is also a function of contact area of both triboelectric material, higher the contact area higher will be the voltage peak 51. As the tapping frequency increased up to 2 Hz of SP-TENG, slightly change in the electrical outputs such as (short circuit current and open circuit voltage) was observed, which can be seen in the Figure 4 b, e. Open circuit voltage increased up to 165 V and short circuit current increased from 0.15 μ A to 5 μ A. Furthermore, we measured electrical outputs at 3Hz tapping frequency and we observed dramatic change in electrical output. Higher frequency leads the open circuit voltage to its peak value of 1400 V and short circuit current reaches to its peak value of 45 μ A. The reason behind this dramatic change in electrical outputs can be attributed to the contact-separation speed and variation in contact surface area ,which is supported by the reported data 53.The dramatical change in the electrical outputs signals can be observed in the results obtained. The electrical performance of nanogenerator was also observed under the varying force such slow, medium and fast hand tapping. The obtained max current after the rectification was measured approximately 35 μ A at fast hand tapping. The short circuit current at different modes of hand tapping is shown in shown in Figure 5 (a, b, c). The electrical performance (such as Voc and Isc) of TENG made up of PTFE as a active layer compared with graphene as active layer TENG to observe the advantages of using two different negative triboelectric materials. Electrical performance (Voc and Isc) of TENG increased by approximately four times when graphene as an active layer was used.(Figure 5d) This prominent effect revealed that graphene is an excellent candidate to serve as negative triboelectric material. In addition to this, graphene oxide has potential to store charge, and can be good candidate for harvesting energy. The results explain the relationship between power density and load resistance. This analysis states that at load resistance of 10 omega-ohms, power density was obtained approximately 2 μ W. The figure demonstrates the total charge accumulate on the surface of tribo-electric material. In triboelectric nanogenerator total charge accumulate at higher frequency, was 120 nC/m2. The maximum charge accumulation is depending upon the total number of electrons transfers and intrinsic properties of material, is also responsible for the higher charge accumulation.

Chrono-amperometric study was performed at total duration 200s and interval time 0.5 s was 0.003mA in the case of plastic base as electrode (Figure 6). SP-TENG generated positive and negative signals which justify the AC current generation. In the start less current was generated because less amount of charge is accumulated in two electrodes. For this, SP-TENG was undergone to same chrono-amperometric conditions. In the next step, the plastic base was coated with aluminum foil and generation of the current was observed. The results in Figure 6b showed that current value increased up to 0.005 mA that was 0.003 mA in the case of plastic (PTFE) base alone. The increase in current was due to modification of plastic surface with aluminum foil that was conductor and facilitated the electron transfer from electrode to outer circuit as compared to plastic. The complete single TENG assembly was fabricated by coating 500 μ m thick graphene oxide layer on aluminum foil. The graphene oxide based SP-TENG was connected to rectifier. The rectifier converted the AC current generated by SP-TENG into dc current, graph showed only positive current signals. The results showed that SP-TENG generated 4.5 mA with 50 fold high frequency as compared to SP-TENG without graphene oxide. In order to increase the current value, two SP-TENG units were connected the in series. After connecting the double unit, chronoampermetric study was performed provided with same conditions. The current generated was 10 mA, which were almost two folds higher than 4.5 mA generated by single SP-TENG unit. Moreover, frequency of current signal was also enhanced many folds by same tapping speed, provided in previous experiments.

Figure 6: Chronamperometric response of SP-TENG plastic (PTFE) (a), PTFE and aluminum foil SP-TENG (b), single unit SP-TENG (c), and double unit SP-TENG (d).

Figure 7: Charge density per unit area accumulate by capacitors

Chronoamperometry was performed to evaluate the electrical behavior of fabricated device as charge storage device (Figure 7). The experiment was performed for total time duration 200s and with interval time 0.5s (Figure 7a). The results revealed that significant current was produced by self-powered TENG. Further application was run to charge 10nF capacitor by SP-TENG and successful results were obtained. The charging and discharging behavior of TENG as capacitor was also evaluated by connecting two commercially available capacitor of 2 μ F and 10 μ F capacitance (Figure 7b). These capacitors are attached with the bridge rectifier. TENG charged the capacitors up to 20 V and 9 V, respectively. The charge accumulation was also observed at different hand tapping speed (Figure 7c, d). The maximum charge density of 100 nC/ m2 achieved at fast hand tapping. Similarly, another capacitor of capacitance 0.3 microfarad was charged at low hand tapping and fast hand tapping. The capacitor charged up to 55 V and 100 V, respectively. This analysis illustrates that present device has potential to harvest biomechanical energy as well as ability to charge the capacitors. The ultimate goal of this device is the real time energy harvesting with reliable and stable behavior.

Renewable energy is current issue of the world because energy sources are going to deplete very fast in the world. The energy is being harvested from many sources around the world. This work designed as a renewable source, which generate the energy cheaply and ecofriendly. The self-powered triboelectric nanogenerator can produced current on tapping. SP-TENG was fabricated by using low cost material like PTFE plastic waste bottles, as a base material, coated with PTFE and aluminum foil as electrodes. The aluminum foil was further coated with graphene oxide to increase the charge generation and transfer. SP-TENG produced the maximum open circuit voltage of 1400V, short circuit current of 45 μ A and has accumulated charge density of 120 nC/m2. The practical application of SP-TENG was tested as capacitor as well. SP-TENG successfully charged the capacitor as described in result and discussion. So, SP-TENG can be used as renewable energy source for various devices.

Authors acknowledge the Institute of Chemical Sciences Bahauddin Zakaryia University Multan for laboratory facilities, WEmpower Pakistan, and Graphene & Advanced 2D Materials Research Group (GAMRG), School of Engineering and Technology, Sunway, University, Malaysia. There is no conflict of interest among the authors

Chen, Haotian, Song, Yu, Guo, Hang, Miao, Liming, Chen, Xuexian, Su, Zongming & Zhang, Haixia . 2018. Hybrid porous micro structured finger skin inspired self-powered electronic skin system for pressure sensing and sliding detection. Nano Energy 51:496–503.

Wang, Sihong, Xu, Jie, Wang, Weichen, Wang, Ging-Ji Nathan, Rastak, Reza, Molina-Lopez, Francisco, Chung, Jong Won, Niu, Simiao, Feig, Vivian R, Lopez, Jeffery, Lei, Ting, Kwon, Soon-Ki, Kim, Yeongin, Foudeh, Amir M, Ehrlich, Anatol, Gasperini, Andrea, Yun, Youngjun, Murmann, Boris, Tok, Null- H & Bao, Zhenan . 2018. Skin electronics from scalable fabrication of an intrinsically stretchable transistor array. Nature 555(7694):83–88.

Chortos, Alex, Liu, Jia & Bao, Zhenan J N M . 2016. Pursuing prosthetic electronic skin. Nature Materials 15(9):937–950.

Gu, Yiding, Zhang, Ting, Chen, Hao, Wang, Feng, Pu, Yueming, Gao, Chunming & Li, Shibin . 2019. Mini Review on Flexible and Wearable Electronics for Monitoring Human Health Information. Nanoscale Research Letters 14(1):1–15.

Wang, Chonghe, Li, Xiaoshi, Hu, Hongjie, Zhang, Lin, Huang, Zhenlong, Lin, Muyang, Zhang, Zhuorui, Yin, Zhenan, Huang, Brady, Gong, Hua, Bhaskaran, Shubha, Gu, Yue, Makihata, Mitsutoshi, Guo, Yuxuan, Lei, Yusheng, Chen, Yimu, Wang, Chunfeng, Li, Yang, Zhang, Tianjiao, Chen, Zeyu, Pisano, Albert P, Zhang, Liangfang, Zhou, Qifa & Xu, Sheng . 2018. Monitoring of the central blood pressure waveform via a conformal ultrasonic device. Nature Biomedical Engineering 2(9):687–695.

Gao, Wei, Emaminejad, Sam, Nyein, Hnin Yin Yin, Challa, Samyuktha, Chen, Kevin, Peck, Austin, Fahad, Hossain M, Ota, Hiroki, Shiraki, Hiroshi, Kiriya, Daisuke, Lien, Der-Hsien, Brooks, George A, Davis, Ronald W & Javey, Ali . 2016. Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Nature 529(7587):509–514.

Chung, Michael, Fortunato, Giuseppino & Radacsi, Norbert J J O T R S I . 2019. Wearable flexible sweat sensors for healthcare monitoring: a review. Journal of The Royal Society Interface 16(159):20190217.

Byun, Junghwan, Lee, Yoontaek, Yoon, Jaeyoung, Lee, Byeongmoon, Oh, Eunho, Chung, Seungjun, Lee, Takhee, Cho, Kyu-Jin, Kim, Jaeha & Hong, Yongtaek . 2018. Electronic skins for soft, compact, reversible assembly of wirelessly activated fully soft robots. Science Robotics 3(18):3.

Lai, Ying-Chih C, Deng, Jianan, Liu, Ruiyuan, Hsiao, Yung-Chi, Zhang, Steven L, Peng, Wenbo, Wu, Hsing-Mei, Wang, Xingfu & Wang, Zhong Lin . 2018. Actively Perceiving and Responsive Soft Robots Enabled by Self-Powered, Highly Extensible, and Highly Sensitive Triboelectric Proximity- and Pressure-Sensing Skins. Advanced Materials 30(28):1801114.

Ju, Hunpyo, Jeong, Jinmo, Kwak, Pyo, Kwon, Minjeong & Lee, Jongho . 2018. Robotic Flexible Electronics with Self-Bendable Films. Soft Robotics 5(6):710–717.

Park, Sungjun, Heo, Soo Won, Lee, Wonryung, Inoue, Daishi, Jiang, Zhi, Yu, Kilho, Jinno, Hiroaki, Hashizume, Daisuke, Sekino, Masaki, Yokota, Tomoyuki, Fukuda, Kenjiro, Tajima, Keisuke & Someya, Takao . 2018. Self-powered ultra-flexible electronics via nano-grating-patterned organic photovoltaics. Nature 561(7724):516–521.

Chen, Jun, Huang, Yi, Zhang, Nannan, Zou, Haiyang, Liu, Ruiyuan, Tao, Changyuan, Fan, Xing & Wang, Zhong Lin . 2016. Micro-cable structured textile for simultaneously harvesting solar and mechanical energy. Nature Energy 1(10):1–8.

Kim, Sun Jin, Lee, Han Eol, Choi, Hyeongdo, Kim, Yongjun J, We, Ju Hyung, Shin, Ji Seon, Lee, Keon Jae & Cho, Byung Jin . 2016. High-Performance Flexible Thermoelectric Power Generator Using Laser Multiscanning Lift-Off Process. ACS Nano 10(12):10851–10857.

Dagdeviren, Canan, Yang, Byung Duk, Su, Yewang, Tran, Phat L, Joe, Pauline, Anderson, Eric, Xia, Jing, Doraiswamy, Vijay, Dehdashti, Behrooz, Feng, Xue, Lu, Bingwei, Poston, Robert, Khalpey, Zain, Ghaffari, Roozbeh, Huang, Yonggang, Slepian, Marvin J & Rogers, John A . 2014. Conformal piezoelectric energy harvesting and storage from motions of the heart, lung, and diaphragm. Proceedings of the National Academy of Sciences 111(5):1927–1932.

Lee, Sungwon, Reuveny, Amir, Reeder, Jonathan, Lee, Sunghoon, Jin, Hanbit, Liu, Qihan, Yokota, Tomoyuki, Sekitani, Tsuyoshi, Isoyama, Takashi, Abe, Yusuke, Suo, Zhigang & Someya, Takao . 2016. A transparent bending-insensitive pressure sensor. Nature Nanotechnology 11(5):472–478.

Guo, Shuang-Zhuang Z, Qiu, Kaiyan, Meng, Fanben, Park, Sung Hyun & Mcalpine, Michael C . 2017. 3D Printed Stretchable Tactile Sensors. Advanced Materials 29(27):1701218.

Liu, Changyong, Huang, Ninggui, Xu, Feng, Tong, Junda, Chen, Zhangwei, Gui, Xuchun, Fu, Yuelong & Lao, Changshi . 2018. 3D Printing Technologies for Flexible Tactile Sensors toward Wearable Electronics and Electronic Skin. Polymers 10(6):629.

Liu, Huicong, Hou, Cheng, Lin, Jiahong, Li, Yunfei, Shi, Qiongfeng, Chen, Tao, Sun, Lining & Lee, Chengkuo . 2018. A non-resonant rotational electromagnetic energy harvester for low-frequency and irregular human motion. Applied Physics Letters 113(20):203901.

Liu, Sheng, Li, Peng & Yang, Yiren J M . 2018. On the design of an electromagnetic aeroelastic energy harvester from nonlinear flutter. Meccanica 53(11-12):2807–2831.

Sardini, E & Serpelloni, M J P E . 2010. Nonlinear electromagnetic generators with polymeric materials for power harvesting from vibrations. Procedia Engineering 5:1168–1171.

Akaydin, Huseyin Dogus, Elvin, Niell & Andreopoulos, Yiannis . 2010. Energy Harvesting from Highly Unsteady Fluid Flows using Piezoelectric Materials. Journal of Intelligent Material Systems and Structures21(13):1263–1278.

Dagdeviren, Canan, Joe, Pauline, Tuzman, Ozlem L, Park, Kwi-Il, Lee, Keon Jae, Shi, Yan, Huang, Yonggang & Rogers, John A . 2016. Recent progress in flexible and stretchable piezoelectric devices for mechanical energy harvesting, sensing and actuation. Extreme Mechanics Letters 9:269–281.

Hobeck, J D & Inman, D J . 2012. Artificial piezoelectric grass for energy harvesting from turbulence-induced vibration. Smart Materials and Structures 21(10):105024.

Wong, Voon-Kean, Ho, Jee-Hou & Chai, Ai-Bao J E . 2017. Performance of a piezoelectric energy harvester in actual rain. Energy 124:364–371.

Petrini, Francesco & Gkoumas, Konstantinos J E . 2018. Piezoelectric energy harvesting from vortex shedding and galloping induced vibrations inside HVAC ducts. Energy and Buildings 158:371–383.

Khan, Usman & Kim, Sang-Woo J A N . 2016. Triboelectric Nanogenerators for Blue Energy Harvesting. ACS Nano 10(7):6429–6432.

Choi, A Young, Lee, Chang Jun, Park, Jiwon, Kim, Dogyun & Kim, Youn Tae . 2017. Corrugated Textile based Triboelectric Generator for Wearable Energy Harvesting. Scientific Reports 7(1):1–6.

Hou, Te-Chien, Yang, Ya, Zhang, Hulin, Chen, Jun, Chen, Lih-Juann & Lin Wang, Zhong . 2013. Triboelectric nanogenerator built inside shoe insole for harvesting walking energy. Nano Energy 2(5):856–862.

Kim, Dong Yeong, Kim, Hyun Soo, Kong, Dae Sol, Choi, Moonkang, Kim, Hak Bum, Lee, Jae-Hyoung, Murillo, Gonzalo, Lee, Minbaek, Kim, Sang Sub & Jung, Jong Hoon . 2018. Floating buoy-based triboelectric nanogenerator for an effective vibrational energy harvesting from irregular and random water waves in wild sea. Nano Energy 45:247–254.

Pu, Xiong, Liu, Mengmeng, Chen, Xiangyu, Sun, Jiangman, Du, Chunhua, Zhang, Yang, Zhai, Junyi, Hu, Weiguo & Wang, Zhong Lin . 2017. Ultrastretchable, transparent triboelectric nanogenerator as electronic skin for biomechanical energy harvesting and tactile sensing. Science Advances 3(5):1700015.

Fan, Feng-Ru, Tian, Zhong-Qun & Lin Wang, Zhong . 2012. Flexible triboelectric generator. Nano Energy 1(2):328–334.

Wang, Z L . 2016. Triboelectric Nanogenerator: Single-Electrode Mode. Springer

Henniker, J J N . 1962. Triboelectricity in Polymers. Nature 196(4853):474.

Jason, Naveen Noah, Shen, Wei & Cheng, Wenlong . 2015. Copper Nanowires as Conductive Ink for Low-Cost Draw-On Electronics. ACS Applied Materials & Interfaces 7(30):16760–16766.

Jiang, Tao, Zhang, Li Min, Chen, Xiangyu, Han, Chang Bao, Tang, Wei, Zhang, Chi, Xu, Liang & Wang, Zhong Lin . 2015. Structural Optimization of Triboelectric Nanogenerator for Harvesting Water Wave Energy. ACS Nano 9(12):12562–12572.

Mariello, M, Guido, F, Mastronardi, V M, Todaro, M T, Desmaële, D & De Vittorio, M . 2019. Nanogenerators for harvesting mechanical energy conveyed by liquids. Nano Energy 57:141–156.

Zhang, Xiao-Sheng, Han, Meng-Di, Meng, Bo & Zhang, Hai-Xia . 2015. High performance triboelectric nanogenerators based on large-scale mass-fabrication technologies. Nano Energy 11:304–322.

Phan, Hai, Shin, Dong-Myeong, Heon Jeon, Sang, Young Kang, Tae, Han, Pyunghwa, Han Kim, Gyu, Kook Kim, Hyung, Kim, Kyujung, Hwang, Yoon-Hwae & Won Hong, Suck . 2017. Aerodynamic and aeroelastic flutters driven triboelectric nanogenerators for harvesting broadband airflow energy. Nano Energy 33:476–484.

Zhang, Lei, Zhang, Binbin, Chen, Jun, Jin, Long, Deng, Weili, Tang, Junfeng, Zhang, Haitao, Pan, Hong, Zhu, Minhao, Yang, Weiqing & Wang, Zhong Lin . 2016. Lawn Structured Triboelectric Nanogenerators for Scavenging Sweeping Wind Energy on Rooftops. Advanced Materials 28(8):1650–1656.

Chen, Xi, He, Jian, Song, Linlin, Zhang, Zengxing, Tian, Zhumei, Wen, Tao, Zhai, Cong, Chen, Yi, Cho, Jundong, Chou, Xiujian & Xue, Chenyang . 2018. Flexible one-structure arched triboelectric nanogenerator based on common electrode for high efficiency energy harvesting and self-powered motion sensing. AIP Advances 8(4):045022.

Pu, Xianjie, Guo, Hengyu, Chen, Jie, Wang, Xue, Xi, Yi, Hu, Chenguo & Wang, Zhong Lin . 2017. Eye motion triggered self-powered mechnosensational communication system using triboelectric nanogenerator. Science Advances 3(7):1700694.

Wen, Rongmei, Guo, Junmeng, Yu, Aifang, Zhang, Ke, Kou, Jinzong, Zhu, Yaxing, Zhang, Yang, Li, Bao-Wen & Zhai, Junyi . 2018. Remarkably enhanced triboelectric nanogenerator based on flexible and transparent monolayer titania nanocomposite. Nano Energy 50:140–147.

Narasimulu, Anand A, Zhao, Pengfei, Soin, Navneet, Prashanthi, Kovur, Ding, Peng, Chen, Jinkai, Dong, Shurong, Chen, Li, Zhou, Erping, Montemagno, Carlo D & Luo, Jikui . 2017. Significant triboelectric enhancement using interfacial piezoelectric ZnO nanosheet layer. Nano Energy 40:471–480.

Ravichandran, Aravind Narain, Ramuz, Marc & Blayac, Sylvain J M C . 2019. Increasing surface charge density by effective charge accumulation layer inclusion for high-performance triboelectric nanogenerators. MRS Communications 9(2):682–689.

Kim, Hyun-Jun, Yim, Eun-Chae, Kim, Jong-Hun, Kim, Seong-Jun, Park, Jeong-Young & Oh, Il-Kwon . 2017. Bacterial Nano?Cellulose Triboelectric Nanogenerator. Nano Energy 33:130–137.

Zhang, Man, Xia, Liangping, Dang, Suihu, Shi, Lifang, Cao, Axiu, Deng, Qiling & Du, Chunlei . 2019. A flexible single-electrode-based triboelectric nanogenerator based on double-sided nanostructures. AIP Advances 9(7):075221.

Nguyen, Vu, Kelly, Steve & Yang, Rusen J A M . 2017. Piezoelectric peptide-based nanogenerator enhanced by single-electrode triboelectric nanogenerator. APL Materials 5(7):074108.

Wang, Meng, Zhang, Nan, Tang, Yingjie, Zhang, Heng, Ning, Chuan, Tian, Lan, Li, Weihan, Zhang, Jiahao, Mao, Yanchao & Liang, Erjun . 2017. Single-electrode triboelectric nanogenerators based on sponge-like porous PTFE thin films for mechanical energy harvesting and self-powered electronics. Journal of Materials Chemistry A 5(24):12252–12257.

Gorham, W F J J O P S P A P C . 1966. A New, General Synthetic Method for the Preparation of Linear Poly-p-xylylenes. Journal of Polymer Science Part A-1: Polymer Chemistry 4(12):3027–3039.

Chen, Ji, Yao, Bowen, Li, Chun & Shi, Gaoquan . 2013. An improved Hummers method for eco-friendly synthesis of graphene oxide. Carbon 64:225–229.

Gomes, A . 2018. Influence of thickness and contact area on the performance of pdms-based triboelectric nanogenerators. arXiv:1803.10070 .

Jie, Yang, Wang, Ning, Cao, Xia, Xu, Ying, Li, Tao, Zhang, Xueji & Wang, Zhong Lin . 2015. Self-Powered Triboelectric Nanosensor with Poly(tetrafluoroethylene) Nanoparticle Arrays for Dopamine Detection. ACS Nano 9(8):8376–8383.

Xia, Kequan, Fu, Jiangming & Xu, Zhiwei J A E M . 2020. Multiple?Frequency High?Output Triboelectric Nanogenerator Based on a Water Balloon for All?Weather Water Wave Energy Harvesting. Advanced Energy Materials 10(28):2000426.

Keywords: Triboelectric nanogenerator, Mechanical energy, Tapping, Aluminum foil, Waste plastic bottle, Single electrode

Materials Innovations (MI) is an interdisciplinary journal devoted to significant experimental and theoretical findings on the synthesis, structure, charachterization, processing and applications of materials. Materials Innovations is dedicated to publishing peer reviewed novel, cutting edge reports of broad interest to the materials science community.