Full Html

Vol 2 Issue 7

Materials for Wearable Sensors

Pages: 188-193

Doi: 10.54738/MI.2022.2702

Doi URL: http://doi.org/10.54738/MI.2022.2702

Mudassar Abbas 1 , Mirza Nadeem Ahmad ?? 2 , Tajamal Hussain 3 , Adnan Mujahid ?? 3

1 School of Textile and Design (STD), University of Management and Technology C-II. Johar Town, Lahore, Pakistan

2 Department of Applied Chemistry, Government College University Faisalabad, Faisalabad, Pakistan

3 School of Chemistry, University of the Punjab, Lahore, 54590, Pakistan

Wearable sensors are the technology of the future and will become an integral part of daily life. These sensors can monitor the physical activities and biochemical information of an individual, organ functions, and environmental changes. A wearable sensor may comprise a sensing element, electrodes, substrate, power unit and data processing unit. Selectivity, sensitivity and reliability of a wearable sensor depend on the sensing element, electrodes and substrate, which can be designed/fabricated with a suitable material. A variety of materials including carbon materials, conductive polymers, metal oxides, metals, elastomers, and nanomaterials have been used depending on the applications of the sensor. In this review, we will summarize the recent developments regarding the use of advanced materials for applications in wearable sensor technologies.

Keywords

Wearable sensors, Electrode materials, Substrate materials, Sensing materials

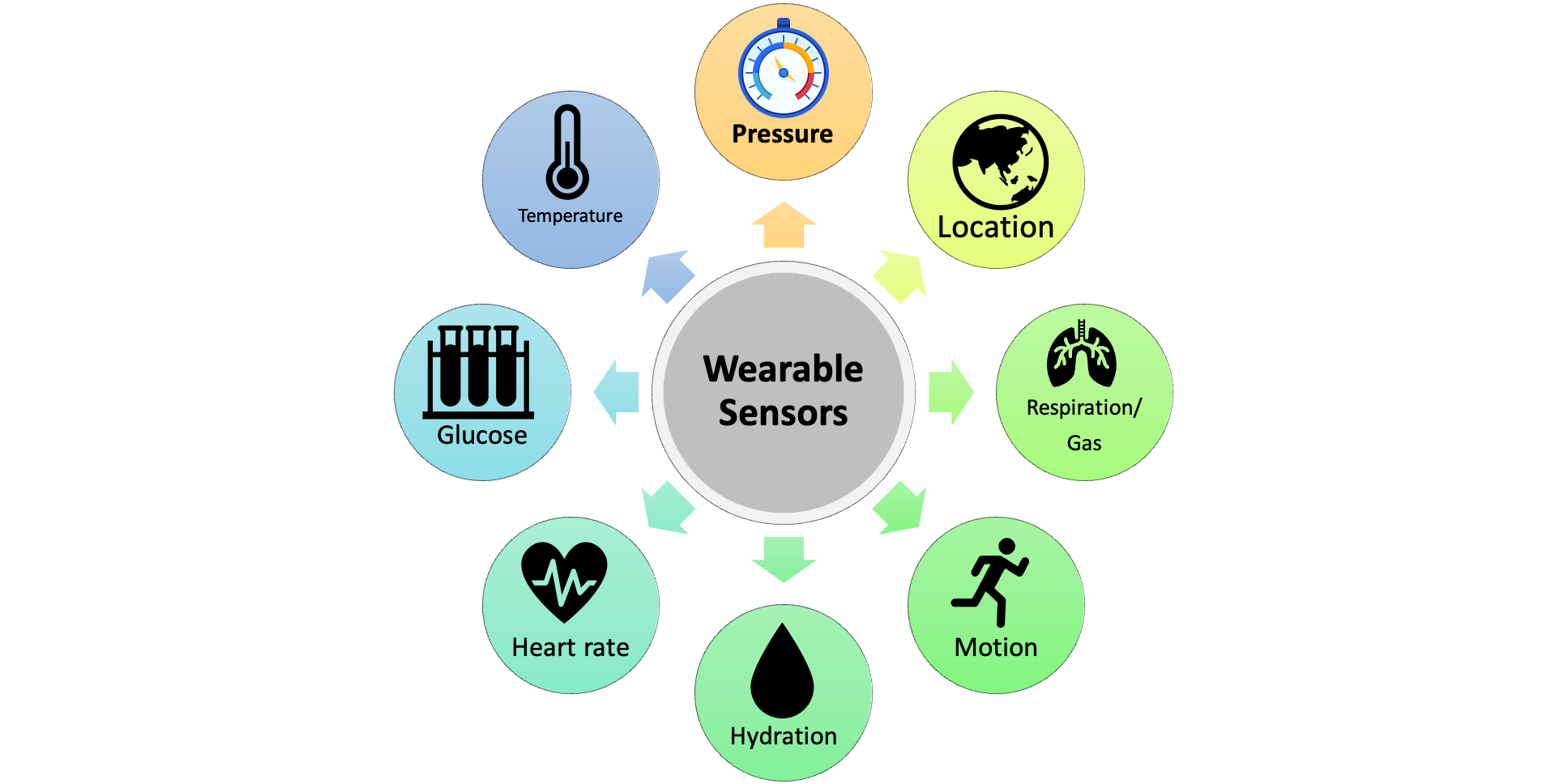

Developments in materials and electronics have led to the development of sensors which can be worn directly on the skin of a person on the desired body part.1 Sensors on the skin can actively monitor the function of the body organs, movement of the person, and the environment in a non-invasive or minimally invasive manner (Figure 1). Such capability of the wearable sensor has revolutionized the point of care (POC) system.2 These wearable sensors when connected with modern information technology, such as 5G, can transmit the sensor data to any centralized system/hospital for remote monitoring of the biometrics of an individual and decision-making/automated response. When integrated with Artificial intelligence/Machine learning, decision-making and response system can be further improved. Initially, wearable devices were integrated with commercial devices such as shoes, wristbands, etc., and could perform simple monitoring such as movement, temperature and heartbeat of an individual.3,4 Now the focus is on specialized medical devices which can perform in a non-invasive or minimally invasive manner for detailed biochemical analysis of an individual.4–6 The next generation of devices will use body fluids to monitor an analyte in the body.

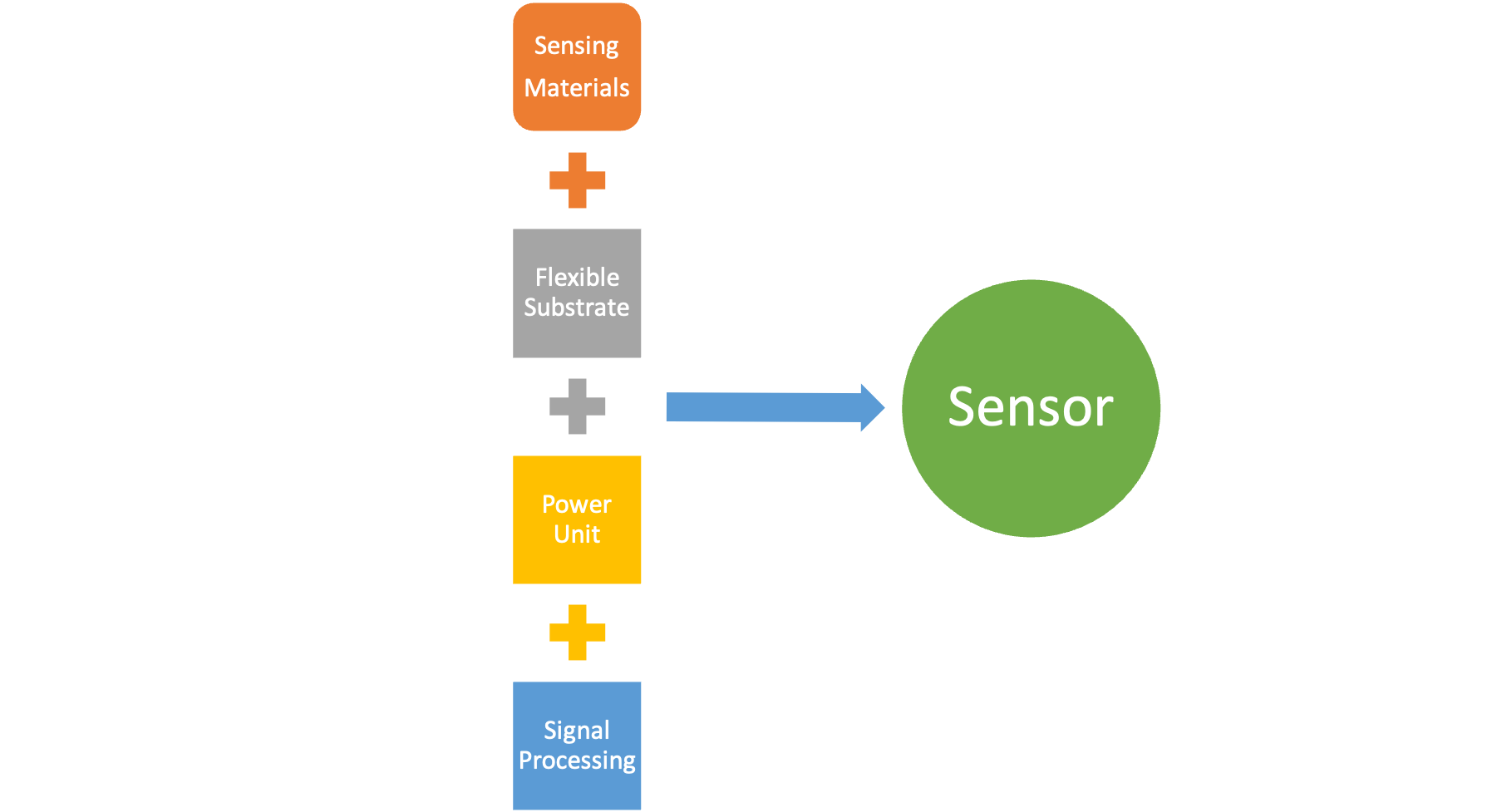

A wearable sensor comprises a sensing element, electrodes, a flexible substrate, a decision-making unit and a power unit (Figure 2).7 Materials play an important part in at least three components of a wearable sensor including the sensing element, electrode and flexible substrate. In this perspective, we will discuss the recent advances in the use of the materials used for sensing elements, flexible substrates and electrodes of wearable sensors.

Figure 1: epresentative applications of wearable sensors

Figure 2: Components of a wearable sensor

Sensing Materials

The sensing material is the key to the selectivity and sensitivity of the wearable sensor. The exact choice of the sensing material depends on the function and mechanism of the sensor. Sensors can work through a range of mechanisms including resistometric, potentiometric, voltammetric, calorimetric, amperometric, resistometric, and FET. Sensing materials can include polymer8–10, carbon materials7,11, nanomaterials (including 0D, 1D, and 2D)12,13 and hybrid materials12,13. As mentioned above, the exact choice of material will depend on the function of the sensor. For temperature sensing applications, sensing material should have a reasonable thermal coefficient of resistance (TCR). Temperature sensing can be performed via the thermal resistance or thermal sensitive field effect transistor (FET). Gold in the form of nanoparticles or foil is a commonly used material for temperature sensing14,15, It has good ductility and can be deposited on a variety of rigid and flexible substrates including SiO2, flexible polymers, and glass, which is a plus for designing wearable sensors.14,15 However, due to low thermal response, the sensing range of gold is limited (>42°C).16 Carbon nanotubes are attractive alternatives due to their excellent thermal response in the temperature range from 20 to 40°C, which can be used in pure form or by compositing with polymers. 17,18Thermally sensitive materials can also be used as channels in FETs for greater sensitivity. For channel materials, graphene (Gr), Gr-related 2D materials, and inorganic-polymer hybrids are materials of choice for flexible and wearable devices.19–22 The detection limit of FET-based devices can reach upto milli-Kelvin.21

For volatile organic compounds (VOCs) from human breath and odor and environmental gases, conducting and semiconducting materials are generally used. Metal oxides23,24, conducting polymers25, MOFs26, solid-state electrolytes27, 2D materials28, carbon nanomaterials29 and dyes28 are sued are used. Dye detection is visual as the analytes when in contact with dyes change the colour of the dyes. Metalloporphyrins (e.g. Cu(II), Zn(II), Mn(II), Co(III), Cr(III), Sn(IV)-based porphyrins, etc.) and some pH-sensitive dyes (e.g. methyl red, bromophenol blue, chlorophenol red, etc.) are among the primary compositions for sensors based on responsive dyes. 30A unique colour map describing the interaction of the VOC with dyes has been generated which can discriminate the VOCs and their concentrations.31 Semiconducting and conducting materials respond to VOCs and gases through changes in electrical properties. The Response of these materials can be tailored or further improved through structural changes. For example, conducting polymers can be functionalized or co-polymerized and metal oxides can take various nano shapes such as nanowires, nanoparticles, nanosheets, nanorods, nanoribbons, nanoflowers, etc.32,33 Metal oxide nanostructure work at relatively low temperature when compared to their bulk counterparts, which is extremely useful for wearable sensors.

For strain/pressure sensing, conductive materials such as carbon materials34,35, metals36, conductive polymers37, 2D materials (Gr, MXenes)38, ionic liquids39, and hybrid micro-/nanostructures are used. Usually, conductive networks of conductive materials (carbon black, CNT, Gr, MXenes, metal nanoparticles, metal nanotubes and rods, etc) are introduced into flexible polymer substrates (Si elastomers, thermoplastic elastomers, rubber, and medical adhesive films).40 Sensors based on these materials have disadvantages of slow response, repeatability, and lifetime.40 Hence, new materials need to be developed to overcome these issues.

Materials for Substrates

Substrates for wearable devices should be flexible, hence, polymers, papers, and textiles are suitable substrate candidates. Amongst polymers, (PI),40 polyethylene terephthalate (PET),41 silk,41 parylene,41 stretchable polydimethyl-siloxane (PDMS)42, acrylic,43 Ecoflex,44 etc. have been widely used flexible/stretchable substrate for wearable devices. The exact choice of the polymer depends on the final application. For example, PI is suitable for high-temperature applications due to its high glass transition temperature45, PET is suitable where high transparency is required and PDMS is suitable for stretchable sensors.46 For in-clothing sensors, textiles are attractive alternates. Textile fibres are compatible to human skin and can act as both sensing material and substrate.47–50 Hence sensors can be fabricated on or can be integrated into the textile fibres. Wool (Animal origin), cotton (plant origin) or synthetic textiles such as Nylon.

Paper is another flexible, low-cost and lightweight substrate used widely for wearable devices. Paper is also biocompatible and environment friendly, as it can self-degrade in ambient, However, the paper has high roughness which is not suitable for smooth film deposition. Moreover, it has large pores, which can trap water and other molecules, leading to large changes in its electrical properties, significantly affecting the accuracy of paper-based wearable devices.49

Figure 3: Summary of the materials used for sensing, substrate and electrodes for wearable sensors

Electrode Materials

Flexible electrode materials are as important as sensing materials and flexible substrates. Ideal electrode material should have excellent electrical conductivity and mechanical properties.46 The structure and electrical property of the electrode should not change under high stress and strain. Attention also needs to be paid to the physics at the sensing material and electrode interface. Interface at the material and electrode can determine the charge injection and extraction. Moreover, the physical bonding between the substrate and the metal is also important as metal films can peel off during the stretching cycles. Conventional metals such as Au,51 Ag,52 Pt,53Al,54 and ITO55 are successfully used as the electrodes for flexible sensors. However, under high stress, metal structures can experience cracks and defects which can change the electrical performance of the electrode materials. To overcome this issue porous metal films have been introduced which can sustain stress and strain more effectively.56 Liquid metals are inherently flexible so these are excellent alternatives for conventional metals as they can deform easily without any structural damage.57 However, it is difficult to pattern these metals due to the unavailability of suitable methods. Conductive polymers58 and Ionic liquids59 are other alternates, which are inherently flexible and stable under stress-strain cycles, however, their conductivity is not comparable to the metals.

2D materials have an excellent combination of electrical properties and mechanical flexibility. For example, Gr has the highest ever reported electron mobility and is flexible yet mechanically toughest material. These properties make Gr and related 2D materials ideal not only as electrode materials but also as sensing elements.60–63 However, Large scale production and a lack of automated transfer methods hamper their widespread applications.64

We have summarized the use of materials for wearable sensor technologies. The performance and application of a wearable sensor can be tailored using device engineering, materials, signal processing, and power use. Materials play an important role in the selectivity, sensitivity, reliability, lifetime, and wearability of a sensor. Hence, a good choice of materials is of critical importance. With the latest developments made in nanomaterials, new avenues have opened for wearable sensor technologies. While a large library of materials for sensing is now available, the focus should be on the choice of the right material for the right application. Even with a wide range of newly available materials, the development of new materials is required for further improvement of wearable sensors. Moreover, reliable large-scale synthesis and processing of nanomaterials are also desirable for the commercialization of wearable sensors based on advanced materials.1

Trung, T Q, Duy, L T, Ramasundaram, S, Lee, N.-E & Transparent, . 2017. Stretchable, and Rapid-Response Humidity Sensor for Body-Attachable Wearable Electronics. Nano Research 10:2021–2033.

Yager, Paul, Domingo, Gonzalo J & Gerdes, John . 2008. Point-of-Care Diagnostics for Global Health. Annual Review of Biomedical Engineering 10(1):107–144.

Iqbal, Sheikh M A, Mahgoub, Imadeldin, Du, E, Leavitt, Mary Ann & Asghar, Waseem . 2021. Advances in healthcare wearable devices. npj Flexible Electronics 5(1):1–14.

Heikenfeld, J, Jajack, A, Rogers, J, Gutruf, P, Tian, L, Pan, T, Li, R, Khine, M, Kim, J & Wang, J . 2018. Wearable Sensors: Modalities, Challenges, and Prospects. Lab on Chip 18(2):217–248.

Brophy, K, Davies, S, Olenik, S, Çotur, Y, Ming, D, Zalk, N Van, O’hare, D, Güder, F & Yetisen, A K . The Future of Wearable Technologies. The Future of Wearable Technologies. 2021 http://www.guderesearch.com/wp-content/uploads/2021/12/IMSJ8878-Wearable-Tech-Briefing-Paper-210601.pdf

Ates, Hatice Ceren, Brunauer, Anna, Stetten, Felix, Urban, Gerald A, Güder, Firat, Merkoçi, Arben, Früh, Susanna Maria & Dincer, Can . 2021. Integrated Devices for Non?Invasive Diagnostics. Advanced Functional Materials 31(15):2010388.

Ates, H Ceren, Nguyen, Peter Q, Gonzalez-Macia, Laura, Morales-Narváez, Eden, Güder, Firat, Collins, James J & Dincer, Can . End-to-end design of wearable sensors. Nature Reviews Materials 2022:1–21.

Brady, S, Lau, K T, Megill, W, Wallace, G G & Diamond, D . 2005. The Development and Characterisation of Conducting Polymeric-based Sensing Devices. Synthetic Metals 154(1-3):25–28.

Zhou, Kangkang, Dai, Kun, Liu, Chuntai & Shen, Changyu . 2020. Flexible conductive polymer composites for smart wearable strain sensors. SmartMat 1(1):1010.

Mokhtar, Siti Musliha Ajmal, Alvarez De Eulate, Eva, Yamada, Miko, Prow, Tarl W & Evans, Drew R . 2021. Conducting polymers in wearable devices. MEDICAL DEVICES & SENSORS 4(1):10160.

Cho, Byungjin, Yoon, Jongwon, Lim, Sung Kwan, Kim, Ah Ra, Kim, Dong-Ho R, Park, Sung-Gyu, Kwon, Jung-Dae, Lee, Young-Joo, Lee, Kyu-Hwan, Lee, Byoung Hun, Ko, Heung Cho & Hahm, Myung Gwan . 2015. Chemical Sensing of 2D Graphene/MoS2 Heterostructure device. ACS Applied Materials & Interfaces 7(30):16775–16780.

Jayathilaka, W A D M, Qi, K, Qin, Y, Chinnappan, A, Serrano-García, W, Baskar, C, Wang, H, He, J, Cui, S & Thomas, S W . 2019. Significance of Nanomaterials in Wearables: A Review on Wearable Actuators and Sensors 31:1805921.

Yao, Shanshan, Swetha, Puchakayala & Zhu, Yong . 2018. Nanomaterial?Enabled Wearable Sensors for Healthcare. Advanced Healthcare Materials 7(1):1700889.

Webb, R Chad, Bonifas, Andrew P, Behnaz, Alex, Zhang, Yihui, Yu, Ki Jun, Cheng, Huanyu, Shi, Mingxing, Bian, Zuguang, Liu, Zhuangjian, Kim, Yun-Soung, Yeo, Woon-Hong, Park, Jae Suk, Song, Jizhou, Li, Yuhang, Huang, Yonggang, Gorbach, Alexander M & Rogers, John A . 2013. Ultrathin conformal devices for precise and continuous thermal characterization of human skin. Nature Materials 12(10):938–944.

Huynh, Tan-Phat & Haick, Hossam . 2016. Self-Healing, Fully Functional, and Multiparametric Flexible Sensing Platform. Advanced Materials 28(1):138–143.

Yang, Jun, Wei, Dapeng, Tang, Linlong, Song, Xuefen, Luo, Wei, Chu, Jin, Gao, Tianpeng, Shi, Haofei & Du, Chunlei . 2015. Wearable temperature sensor based on graphene nanowalls. RSC Advances5(32):25609–25615.

Matzeu, G, Pucci, A, Savi, S, Romanelli, M & Di Francesco, F . 2012. A temperature sensor based on a MWCNT/SEBS nanocomposite. Sensors and Actuators A: Physical 178:94–99.

Giuliani, Alessio, Placidi, Massimo, Di Francesco, Fabio & Pucci, Andrea . 2014. A new polystyrene-based ionomer/MWCNT nanocomposite for wearable skin temperature sensors. Reactive and Functional Polymers 76:57–62.

Tien, Nguyen Thanh, Jeon, Sanghun, Kim, Do-Il, Trung, Tran Quang, Jang, Mi, Hwang, Byeong-Ung, Byun, Kyung-Eun, Bae, Jihyun, Lee, Eunha, Tok, Null- H, Bao, Zhenan, Lee, Nae-Eung & Park, Jong-Jin . 2014. A Flexible Bimodal Sensor Array for Simultaneous Sensing of Pressure and Temperature. Advanced Materials 26(5):796–804.

Kaltenbrunner, Martin, Sekitani, Tsuyoshi, Reeder, Jonathan, Yokota, Tomoyuki, Kuribara, Kazunori, Tokuhara, Takeyoshi, Drack, Michael, Schwödiauer, Reinhard, Graz, Ingrid, Bauer-Gogonea, Simona, Bauer, Siegfried & Someya, Takao . 2013. An ultra-lightweight design for imperceptible plastic electronics. Nature 499(7459):458–463.

Yokota, Tomoyuki, Inoue, Yusuke, Terakawa, Yuki, Reeder, Jonathan, Kaltenbrunner, Martin, Ware, Taylor, Yang, Kejia, Mabuchi, Kunihiko, Murakawa, Tomohiro, Sekino, Masaki, Voit, Walter, Sekitani, Tsuyoshi& Someya, Takao . 2015. Ultraflexible, large-area, physiological temperature sensors for multipoint measurements. Proceedings of the National Academy of Sciences 112(47):14533–14538.

Trung, Tran Quang, Ramasundaram, Subramaniyan, Hwang, Byeong-Ung & Lee, Nae-Eung . 2016. An All-Elastomeric Transparent and Stretchable Temperature Sensor for Body-Attachable Wearable Electronics. Advanced Materials 28(3):502–509.

Hangarter, Carlos M, Chartuprayoon, Nicha, Hernández, Sandra C, Choa, Yongho & Myung, Nosang V . 2013. Hybridized conducting polymer chemiresistive nano-sensors. Nano Today 8(1):39–55.

Korotcenkov, G . 2007. Metal Oxides for Solid-State Gas Sensors: What Determines Our Choice? Materials Science and Engineering: B 139:1–23.

Bai, Hua & Shi, Gaoquan . 2007. Gas Sensors Based on Conducting Polymers. Sensors 7(3):267–307.

Li, Hai-Yang, Zhao, Shu-Na, Zang, Shuang-Quan & Li, Jing . Functional metal–organic frameworks as effective sensors of gases and volatile compounds. Chemical Society Reviews 49(17):6364–6401.

Mulmi, S & Thangadurai, . Solid-State Electrochemical Carbon Dioxide Sensors: Fundamentals, Materials and Applications . Journal of The Electrochemical Society 2020:37567.

Silvestri, A, Wetzl, C, Alegret, N, Cardo, L, Hou, H.-L, Criado, A & Prato, M . The Era of Nano-Bionic: 2D Materials for Wearable and Implantable Body Sensors. Advanced Drug Delivery Reviews 2022. 114315

Erdem, Özgecan, Derin, Esma, Zeibi Shirejini, Saeedreza, Sagdic, Kutay, Yilmaz, Eylul Gulsen, Yildiz, Selvin, Akceoglu, Garbis Atam & Inci, Fatih . 2022. Carbon?Based Nanomaterials and Sensing Tools for Wearable Health Monitoring Devices. Advanced Materials Technologies 7(3):2100572.

Askim, Jon R, Mahmoudi, Morteza & Suslick, Kenneth S . 2013. Optical sensor arrays for chemical sensing: the optoelectronic nose. Chemical Society Reviews 42(22):8649.

Han, F, Inoue, T, Wasai, T, Ku-Raochi, Y & Ohga, K . 2006. Odor Sensor Based on the Information of Colour. J. Eng Appl. Sci 1:1–6.

Alrammouz, R, Podlecki, J, Abboud, P, Sorli, B & Habchi, R . 2018. A Review on Flexible Gas Sensors: From Materials to Devices. Sensors and Actuators A: Physical 284:209–231.

Bautista-Quijano, Jose Roberto, Torres, Renato & Kanoun, Olfa . 2018. Flexible strain sensing filaments based on styrene-butadiene-styrene co-polymer mixed with carbon particle filled thermoplastic polyurethane. 2018 Nanotechnology for Instrumentation and Measurement (NANOfIM) 1–3.

Amjadi, Morteza, Yoon, Yong Jin & Park, Inkyu . 2015. Ultra-stretchable and skin-mountable strain sensors using carbon nanotubes–Ecoflex nanocomposites. Nanotechnology 26(37):375501.

Amjadi, Morteza, Turan, Mehmet, Clementson, Cameron P & Sitti, Metin . 2016. Parallel Microcracks-based Ultrasensitive and Highly Stretchable Strain Sensors. ACS Applied Materials & Interfaces8(8):5618–5626.

Kim, Kyun Kyu, Hong, Sukjoon, Cho, Hyun Min, Lee, Jinhwan, Suh, Young Duk, Ham, Jooyeun & Ko, Seung Hwan . 2015. Highly Sensitive and Stretchable Multidimensional Strain Sensor with Prestrained Anisotropic Metal Nanowire Percolation Networks. Nano Letters 15(8):5240–5247.

Chen, Jianwen, Yu, Qunli, Cui, Xihua, Dong, Mengyao, Zhang, Jiaoxia, Wang, Chao, Fan, Jincheng, Zhu, Yutian & Guo, Zhanhu . An overview of stretchable strain sensors from conductive polymer nanocomposites. Journal of Materials Chemistry C 7(38):11710–11730.

Ma, Ziang, Ma, Keming, Lu, Shaowei, Wang, Sai, Liu, Xingmin, Li, Bohan, Zhang, Lu & Wang, Xiaoqiang . 2020. Flexible Ti3C2Tx MXene/ink human wearable strain sensors with high sensitivity and a wide sensing range. Sensors and Actuators A: Physical 315:112304.

Choi, Dong Yun, Kim, Min Hyeong, Oh, Yong Suk, Jung, Soo-Ho, Jung, Jae Hee, Sung, Hyung Jin, Lee, Hyung Woo & Lee, Hye Moon . 2017. Highly Stretchable, Hysteresis-Free Ionic Liquid-Based Strain Sensor for Precise Human Motion Monitoring. ACS Applied Materials & Interfaces 9(2):1770–1780.

Souri, Hamid, Banerjee, Hritwick, Jusufi, Ardian, Radacsi, Norbert, Stokes, Adam A, Park, Inkyu, Sitti, Metin & Amjadi, Morteza . 2020. Wearable and Stretchable Strain Sensors: Materials, Sensing Mechanisms, and Applications. Advanced Intelligent Systems 2(8):2000039.

Kim, Sungho, Han, Jinkyu, Kang, Null- A, Song, Wooseok, Myung, Sung, Kim, Sang-Woo, Lee, Sun Sook, Lim, Jongsun & An, Ki-Seok . 2018. Flexible chemical sensors based on hybrid layer consisting of molybdenum disulphide nanosheets and carbon nanotubes. Carbon 129:607–612.

Nag, Anindya, Simorangkir, Roy B V B, Valentin, Elizabeth, Bjorninen, Toni, Ukkonen, Leena, Hashmi, Raheel M & Mukhopadhyay, Subhas Chandra . 2018. A Transparent Strain Sensor Based on PDMS-Embedded Conductive Fabric for Wearable Sensing Applications. IEEE Access 6:71020–71027.

Song, Zhilong, Huang, Zhao, Liu, Jingyao, Hu, Zhixiang, Zhang, Jianbing, Zhang, Guangzu, Yi, Fei, Jiang, Shenglin, Lian, Jiabiao, Yan, Jia, Zang, Jianfeng & Liu, Huan . 2018. Fully Stretchable and Humidity-Resistant Quantum Dot Gas Sensors. ACS Sensors 3(5):1048–1055.

Zhang, Shuo, Wen, Lei, Wang, Huan, Zhu, Kai & Zhang, Min . Vertical CNT–Ecoflex nanofins for highly linear broad-range-detection wearable strain sensors. Journal of Materials Chemistry C 6(19):5132–5139.

Li, Mengmeng, Chen, Xian, Li, Xiuting, Dong, Jie, Zhao, Xin & Zhang, Qinghua . 2021. Wearable and Robust Polyimide Hydrogel Fiber Textiles for Strain Sensors. ACS Applied Materials & Interfaces13(36):43323–43332.

Wang, Xuewen, Liu, Zheng & Zhang, Ting . 2017. Flexible Sensing Electronics for Wearable/Attachable Health Monitoring. Small 13(25):1602790.

Afroj, Shaila, Karim, Nazmul, Wang, Zihao, Tan, Sirui, He, Pei, Holwill, Matthew, Ghazaryan, Davit, Fernando, Anura & Novoselov, Kostya S . 2019. Engineering Graphene Flakes for Wearable Textile Sensors via Highly Scalable and Ultrafast Yarn Dyeing Technique. ACS Nano 13(4):3847–3857.

Soh, Ping Jack, Van Den Bergh, Bertold, Xu, Hantao, Aliakbarian, Hadi, Farsi, Saeed, Samal, Purna, Vandenbosch, Guy A E, Schreurs, Null- P & Nauwelaers, Bart K J C . 2013. A smart wearable textile array system for biomedical telemetry applications. IEEE Transactions on Microwave Theory and Techniques 61(5):2253–2261.

Chuang, Min-Chieh, Windmiller, Joshua Ray, Santhosh, Padmanabhan, Ramírez, Gabriela Valdés, Galik, Michal, Chou, Tzu-Yang & Wang, Joseph . 2010. Textile-based Electrochemical Sensing: Effect of Fabric Substrate and Detection of Nitroaromatic Explosives. Electroanalysis 22(21):2511–2518.

Chuang, Cheng?hsun & Kung, Chung?wei . 2020. Metal−Organic Frameworks toward Electrochemical Sensors: Challenges and Opportunities. Electroanalysis 32(9):1885–1895.

Choi, Seon-Jin, Kim, Sang-Joon & Kim, Il-Doo . 2016. Ultrafast optical reduction of graphene oxide sheets on colorless polyimide film for wearable chemical sensors. NPG Asia Materials 8(9):e315.

Smith, Merry K & Mirica, Katherine A . 2017. Self-Organized Frameworks on Textiles (SOFT): Conductive Fabrics for Simultaneous Sensing, Capture, and Filtration of Gases. Journal of the American Chemical Society 139(46):16759–16767.

Huang, Yifan, Jiao, Weicheng, Chu, Zhenming, Nie, Xinmiao, Wang, Rongguo & He, Xiaodong . 2020. SnS2 Quantum Dot-Based Optoelectronic Flexible Sensors for Ultrasensitive Detection of NO2 Down to 1 ppb. ACS Applied Materials & Interfaces 12(22):25178–25188.

Asad, Mohsen, Sheikhi, Mohammad Hossein, Pourfath, Mahdi & Moradi, Mahmood . 2015. High sensitive and selective flexible H2S gas sensors based on Cu nanoparticle decorated SWCNTs. Sensors and Actuators B: Chemical 210:1–8.

Song, Jun?kyul, Son, Donghee, Kim, Jaemin, Yoo, Young Jin, Lee, Gil Ju, Wang, Liu, Choi, Moon Kee, Yang, Jiwoong, Lee, Mincheol J, Do, Kyungsik, Koo, Ja Hoon, Lu, Nanshu, Kim, Ji Hoon, Hyeon, Taeghwan, Song, Young Min & Kim, Dae?hyeong . 2017. Wearable Force Touch Sensor Array Using a Flexible and Transparent Electrode. Advanced Functional Materials 27(6):1605286.

Guo, Shiqi, Yang, Dong, Zhang, Sheng, Dong, Quan, Li, Baichen, Tran, Nam, Li, Zhenyu, Xiong, Yujie & Zaghloul, Mona E . 2019. Development of a Cloud?Based Epidermal MoSe2 Device for Hazardous Gas Sensing. Advanced Functional Materials 29(18):1900138.

Trung, T Q, Hanif, A, Siddiqui, S, Roh, E, Lee, W & Lee, N.-E . A Stretchable and Highly Sensitive Chemical Sensor Using Multilayered Network of Polyurethane Nanofibres with Self-Assembled Reduced Graphene Oxide. 2D Materials 2017(2):25062.

Takamatsu, Seiichi, Lonjaret, Thomas, Ismailova, Esma, Masuda, Atsuji, Itoh, Toshihiro & Malliaras, George G . 2016. Wearable Keyboard Using Conducting Polymer Electrodes on Textiles. Advanced Materials28(22):4485–4488.

Wang, Binghao, Thukral, Anish, Xie, Zhaoqian, Liu, Limei, Zhang, Xinan, Huang, Wei, Yu, Xinge, Yu, Cunjiang, Marks, Tobin J & Facchetti, Antonio . 2020. Flexible and stretchable metal oxide nanofiber networks for multimodal and monolithically integrated wearable electronics. Nature Communications 11(1):1–11.

Zhou, Dong, Zhao, Liang & Li, Bo . 2021. Recent progress in solution assembly of 2D materials for wearable energy storage applications. Journal of Energy Chemistry 62:27–42.

Zazoum, Bouchaib, Bachri, Abdel & Nayfeh, Jamal . Functional 2D MXene Inks for Wearable Electronics. Materials 14(21):6603.

Silvestri, A, Wetzl, C, Alegret, N, Cardo, L, Hou, H.-L, Criado, A & Prato, M . 2022. The Era of Nano-Bionic: 2D Materials for Wearable and Implantable Body Sensors. Advanced Drug Delivery Reviews 114315.

Pang, Yu, Yang, Zhen, Yang, Yi & Ren, Tian?ling . 2020. Wearable Electronics Based on 2D Materials for Human Physiological Information Detection. Small 16(15):1901124.

Avishan, Nardin, Hussain, Naveed & Nosheen, Farhat . 2022. Large-Scale Graphene Production and Transfer for Industrial Applications. Materials Innovtions 2(1):15–25.

Keywords: Sensing materials,Substrate materials ,Electrode materials ,Wearable sensors

Materials Innovations (MI) is an interdisciplinary journal devoted to significant experimental and theoretical findings on the synthesis, structure, charachterization, processing and applications of materials. Materials Innovations is dedicated to publishing peer reviewed novel, cutting edge reports of broad interest to the materials science community.